Lined Pipe and Fittings

UNPPolyvalves, specializes in the production of robust and corrosion-resistant lined pipe and fittings. Crafted with precision, UNP’s lined pipes boast a resilient PTFE liner, with the option to upgrade to Dyneon TFM for enhanced performance. Fabricated from premium carbon or stainless steel, each pipe is meticulously constructed with diameter ranges from 1/2 inch up to 20 inches. UNP’s product line includes a variety of ANSI class 150, 300, and DIN flange dimensions, offering flexibility to suit diverse industrial needs. Additionally, explore our range of optional features such as specialized coatings and extended vent holes for tailored solutions.

Expert Assistance

Connect with a our sales engineers to get a quote or more information about our Lined Pipe Product offerings

Key Features

Heat Resistant

Corrosion Resistant

Carbon or Stainless Steel

ASTM Certified

Pipe Fittings

View the UNP Pipe and Fittings Product Brochure for more specifications, material compositions, and testing data.

Available Lining Material

- PTFE

- PVDF

- PPH

- HDPE

- TFM

Pipe Material of Construction

- Stainless Steel

- Carbon Steel

Pipe Spool

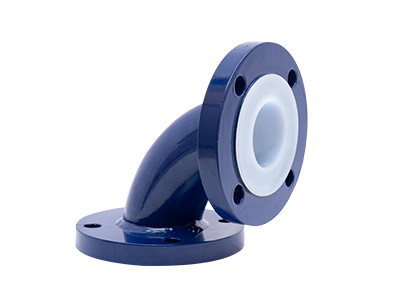

90 Degree Elbow

45 Degree Elbow

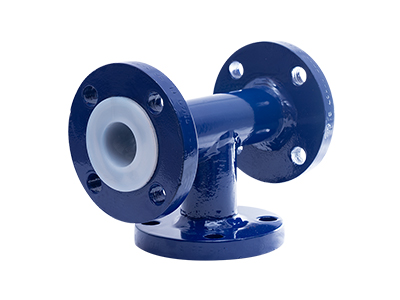

Equal Tee

Material Specs

- Pipe: Seamless Carbon Steel – As per ASTM A 106 GR.B, SCH 20 (up to 6″ and Above 6″)

- Flange: A105 -150#

- Lining: PTFE Conforming ASTM D4895

Material Specs

- 90°: Seamless Carbon Steel – ASTM A 234 GR. WPB, SCH 40 (up to 6″) / SCH 20 (Above 6″)

- Flange: ASTM A 105 – As per ASME B 16.5, 150#

- Lining: PTFE Conforming ASTM D4895

Material Specs

- 45° Bend: Seamless Carbon Steel – ASTM A 234 GR. WPB, SCH 40 (up to 6″) / SCH 20 (Above 6″)

- Flange: ASTM A 105 – As per ASME B 16.5, 150#

- Lining: PTFE Conforming ASTM D4895

Material Specs

- Eq. Tee: Seamless Carbon Steel – As per ASTM A 106 GR. B, SCH 40 (up to 6″) / SCH 20 (Above 6″)

- Flange: ASTM A 105 – As per ASME B 16.5, 150#

- Lining: PTFE Conforming ASTM D3307

Equal Cross

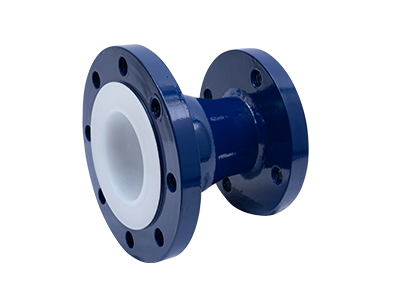

Reducer Fitting

Unequal Tee

Reducing Flanges

Material Specs

- Pipe: Seamless Carbon Steel – As per ASTM A 106 GR.B, SCH 20 (up to 6″ and Above 6″)

- Flange: A105 -150#

- Lining: PTFE Conforming ASTM D4895

Material Specs

- Reducer: Seamless Carbon Steel – ASTM A 216 GR.WCB

- Flange: As per ASME B 16.5, 150#

- Lining: PTFE Conforming ASTM D3307

Material Specs

- Un. Eq. Tee: Seamless Carbon Steel – ASTM A 106 GR.B, SCH 40 (up to 6″) / SCH 20 (Above 6″)

- Flange: ASTM A 105 – As per ASME B 16.5, 150#

- Lining: PTFE Conforming ASTM D3307

Material Specs

- Reducing Flange: IS 2062

- Flange: As per ASME B 16.5, 150#

- Lining: PFA Conforming ASTM D3307

Pipe Specifications

Use the chart below to find UNP pipe specifications and dimensions.

Need to speak with a representative?

Size | L – ID (Ød) | ØR / F (ØB) | F. OD (ØD) | F. THK (G) | Stub End (T) | P.C.D. (K) | H – DIA (Øe) | NH (n) | Lining THK (S) | C. S. Pipe (SCH) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | |||

0.079 | ±2 | 0.079 | ±2 | 0.06 | ±1.6 | |||||||||||||

1/2″ | 0.39 | 10 | 1.37 | 34.9 | 3.50 | 88.9 | 0.44 | 11.1 | 0.35 | 8.9 | 2.37 | 60.3 | 0.63 | 15.9 | 04 | 0.126 | 3.2 | 40 |

3/4″ | 0.59 | 15 | 1.68 | 42.7 | 3.87 | 98.4 | 0.50 | 12.7 | 0.40 | 10.2 | 2.75 | 69.8 | 0.63 | 15.9 | 04 | 0.126 | 3.2 | 40 |

1″ | 0.79 | 20 | 2.01 | 51 | 4.25 | 108 | 0.56 | 14.2 | 0.45 | 11.4 | 3.13 | 79.4 | 0.63 | 15.9 | 04 | 0.126 | 3.2 | 40 |

1.5″ | 1.34 | 34 | 2.87 | 73 | 5.00 | 127 | 0.69 | 17.5 | 0.55 | 14 | 3.87 | 98.4 | 0.63 | 15.9 | 04 | 0.126 | 3.2 | 40 |

2″ | 1.73 | 44 | 3.62 | 92 | 6.00 | 152.4 | 0.75 | 19 | 0.60 | 15.2 | 4.75 | 120.6 | 0.75 | 19 | 04 | 0.138 | 3.5 | 40 |

3″ | 2.76 | 70 | 5.00 | 127 | 7.50 | 190.5 | 0.94 | 23.8 | 0.75 | 19.0 | 6.00 | 152.4 | 0.75 | 19 | 04 | 0.157 | 4 | 40 |

4″ | 3.70 | 94 | 6.18 | 157 | 9.00 | 228.6 | 0.94 | 23.8 | 0.75 | 19.0 | 7.50 | 190.5 | 0.75 | 19 | 08 | 0.177 | 4.5 | 40 |

6″ | 5.67 | 144 | 8.50 | 216 | 11.00 | 279.4 | 1.00 | 25.4 | 0.80 | 20.3 | 9.50 | 241.3 | 0.87 | 22.2 | 08 | 0.217 | 5.5 | 40 |

8″ | 7.64 | 194 | 10.63 | 270 | 13.50 | 342.9 | 1.13 | 28.6 | 0.90 | 22.9 | 11.75 | 298.4 | 0.87 | 22.2 | 08 | 0.217 | 5.5 | 20 |

10″ | 9.72 | 247 | 12.76 | 324 | 16.00 | 406.4 | 1.19 | 30.2 | 0.95 | 24.2 | 14.25 | 362 | 1.00 | 25.4 | 12 | 0.256 | 6.5 | 20 |

12″ | 11.73

| 298 | 15.00 | 381 | 19.00 | 482.6 | 1.25 | 31.8 | 1.00 | 25.4 | 17.00 | 431.8 | 1.00 | 25.4 | 12 | 0.256 | 6.5 | 20 |

14″ | 12.83 | 326 | 13.26 | 413 | 21.00 | 533.4 | 1.37 | 34.9 | 1.10 | 27.9 | 18.75 | 476.3 | 1.13 | 28.6 | 12 | 0.256 | 6.5 | 20 |

16″ | 14.84 | 377 | 18.50 | 470 | 23.50 | 596.9 | 1.44 | 36.5 | 1.15 | 29.2 | 21.25 | 539.8 | 1.13 | 28.6 | 16 | 0.256 | 6.5 | 20 |

18″ | 16.85 | 428 | 21.00 | 533.4 | 25.00 | 635 | 1.56 | 39.7 | 1.25 | 31.8 | 22.75 | 577.9 | 1.25 | 31.8 | 16 | 0.256 | 6.5 | 20 |

20″ | 18.70 | 475 | 23.00 | 584.2 | 27.50 | 698.5 | 1.69 | 42.9 | 1.35 | 34.3 | 25.00 | 635 | 1.26 | 32 | 20 | 0.256 | 6.5 | 20 |

TFM Dyneon Liner Features

*Upgradeable Option

- Lower Deformation Under Load – Compared to conventional PTFE, Dyneon TFM maintains its shape and integrity when subjected to substantially higher pressures.

- Denser Polymer Structure – Dyneon TFM has fewer voids resulting in lower permeability compared to PTFE. This makes it more resistant to the passage of gasses or liquids through its surface.

- Improved Stress Recovery – Dyneon TFM recovers from stress more efficiently, especially at elevated temperatures, therefore it maintains its sealing properties for longer resulting in longer lasting pipe and less maintenance.

Request a Quote

CPE experts are ready to help advise and provide you with the information you need. Use the form below to request a quote or consultation.