Monitor Oil Level

Isolators play a crucial function in preventing oil leakage and contamination of the bearings, housings, and the oil itself. However, isolators only work effectively when they are maintained using the necessary best practices.

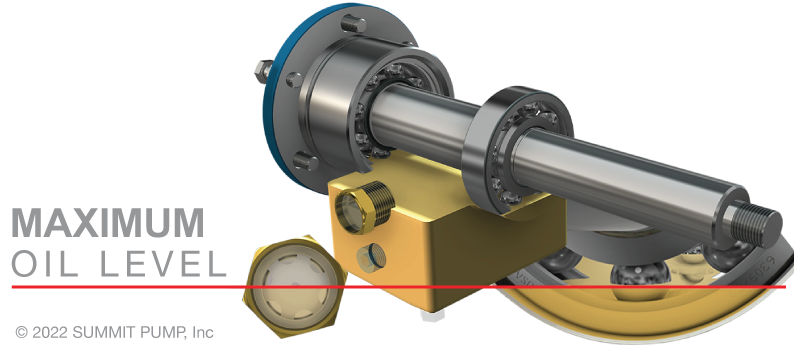

Maintaining the oil level inside the cavity appropriately, that is, neither too high nor too low, is a technique that is frequently neglected. The sight glass must be halfway full to prevent reliability problems. A half-full sight glass indicates that the oil level is in the center of the bearing’s bottom-most ball. The bearing will overheat and wear out more quickly if the oil is overfilled. Underfilling the cavity will result in inadequate lubrication and failure of the bearing.

*Take note that you must level the pump and motor if the sight glass shows that the oil level is halfway full but the bottom ball bearing is not completely submerged in oil.

We Specialize in Pump Reliability

Our experts have proven track record of designing solutions to improve pump reliability. Contact us to begin improving your reliability and improving mean time between failure