Strong cases for CPE services

Effective maintenance. Smart system design. Efficiency and cost savings. These are just some of the attributes of a CPE service solution.

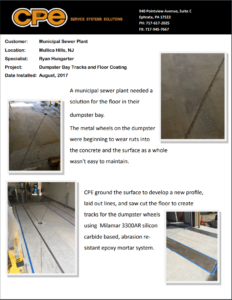

New Floor at a Municipal Sewer Plant

A municipal sewer plant needed a solution for a floor in their dumpster bay. CPE ground the surface to develop a new profile, laid out lines, and saw cut the floor to create tracks for the dumpster wheels using Milamar 3300AR silicon carbide based, abrasion resistant epoxy mortar system. The remaining floor surface was coated with Milamar ICO Floor SL self-leveling epoxy and top-coated with Milamar PM 500 yellow urethane for added protection.

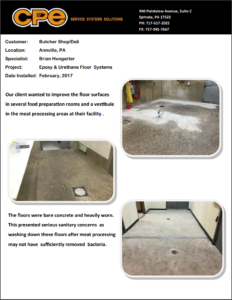

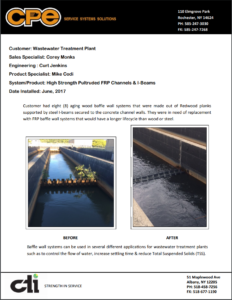

Replacement FRP Ball Wall System at a Wastewater Treatment Facility

Replacement FRP Ball Wall System at a Wastewater Treatment Facility

Baffle wall systems can be used in several different applications for wastewater treatment plants such as to control the flow of water, increase settling time & reduce Total Suspended Solids (TSS). In this case, the FRP Baffle Wall Systems were designed and approved prior to fabrication in shop and field installation at site.

Replacing Progressive Cavity Pumps

A large-scale municipal waste water treatment facility in Western NY State had an installed base of progressive cavity pumps for delivery sludge to the filter press. These pumps required constant maintenance and replacement parts and on an annual basis rivaled the cost of a new pump.

CC-100 Ceramic Coating – Corrosion Resistant Radiant Heat Barrier

CC-100 was utilized to reduce the ambient temperature of a vault occupied by active steam piping from 160°F to a safe working environment at 120°F.

Concrete Repair & High Performance Lining

A process drainage ditch had severely deteriorated concrete and corroded steel frame. Previous concrete patches were not effective in the acidic environment.

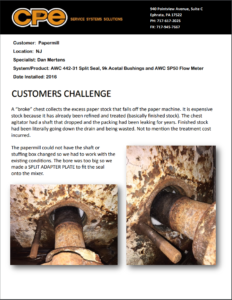

A.W. Chesterton Split Seal and Flush Reducing SpiralTrac Bushing

By converting from packing to a split mechanical seal and SpriralTrac bushing, a large municipal waste treatment facility is realizing an 85% reduction in water consumption.